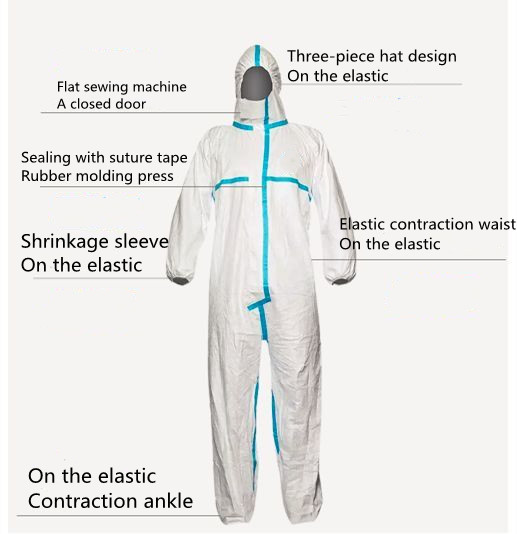

Medical microporous coverall usually consists of a one-piece structure consisting of hats, tops, and pants. There are strict standards in the production, including protection (sealing), usability, safety and hygiene. The medical protective clothing that can be made by cutting, stitching, tightening, and bonding adhesive strips is inseparable from the three types of machines involved: flat stitching, overlock stitching, and laminating.

Basic stitch

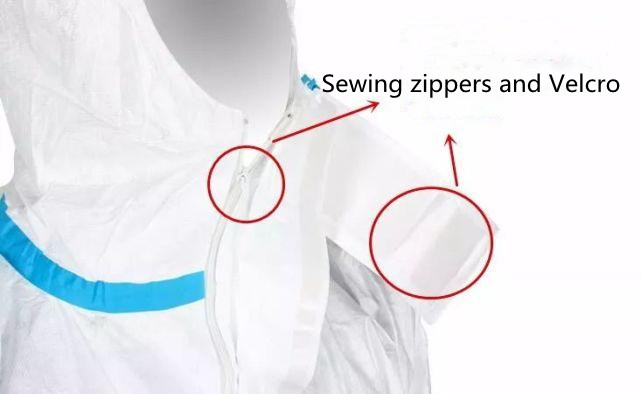

Zipper, Velcro

Medical microporous coverall usually uses a closed placket design, that is, the internal zipper is closed, the external placket is glued, and the zipper and velcro are attached through flat seams. In addition to better putting on and taking off, this design can make the fit closer

Elastic bands on cuffs, ankles, hats

Waist compression elastic

In order to facilitate movement and work, and provide better flexibility for wearing, the waist of protective microporous coverall clothing is usually tightened with elastic elastic bands through a lockstitch machine to increase work efficiency and use safety

Adhesive tape

In addition to the above design, the most important step is inseparable from the reason why such a high sealing performance can be achieved. After the lathe has sewn the protective clothing, all stitches and pinholes in the protective clothing need to be glued and sealed by a press machine to prevent dust or liquid from entering the sewing pinholes, and enhance the isolation performance and use of the protective clothing Safety